Harmonic Drive Gears

Our quality Harmonic Drive gears gives you clear advantages over traditional gear solutions.

Harmonic Drive gears gives you clear advantages

With harmonic gears you can achieve many benefits such as zero backlash, high dynamics, lower production costs, excellent lifetime precision, consistent quality, Increased operating reliability in a simple compact and lightweight design.

Harmonic Drive gears are typically used in industrial motion control, machine tool, printing machine, robotics and aerospace, for gear reduction but may also be used to increase rotational speed, or for differential gearing.

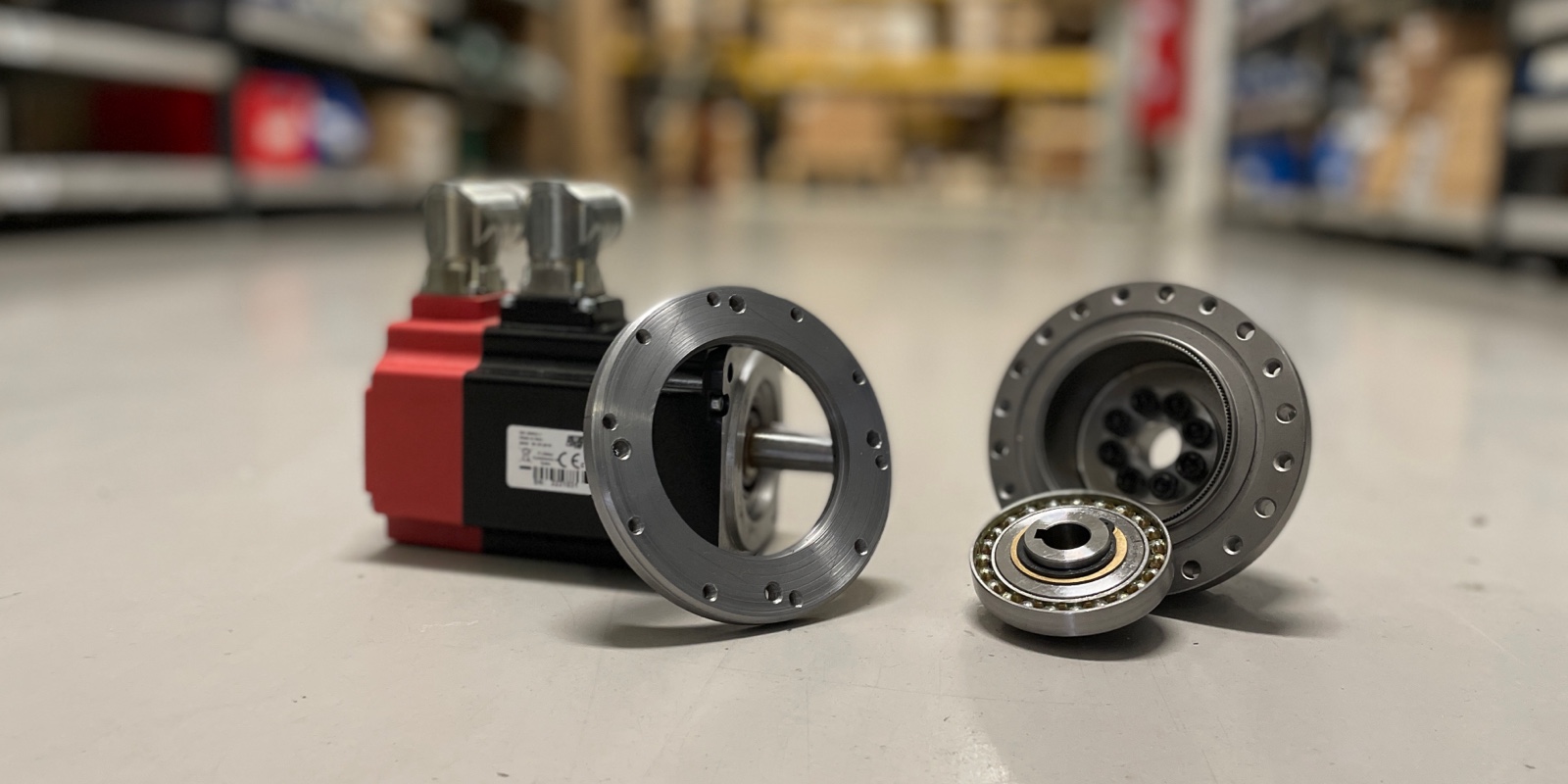

We manufacture customized high-quality flanges for all Harmonic Drive gears in-house in our own workshop for all types of electric motors – whether it is AC, DC or torque motors – Your guarantee for the best quality and fastest delivery time.

Read more about our harmonic drive gear below or call us now (+45) 70 15 14 14 for ordering and questions.

Harmonic Drive Gear CCS-II

The universal compact and lightweight CCS-II Harmonic Drive gear gives you zero backlash, high dynamics, excellent lifetime precision and consistent quality. We manufacture customized flanges that fit exactly between the Harmonic 1CCS-II Drive gear and your AC, DC or torque motors. Download catalog or call us now for ordering.

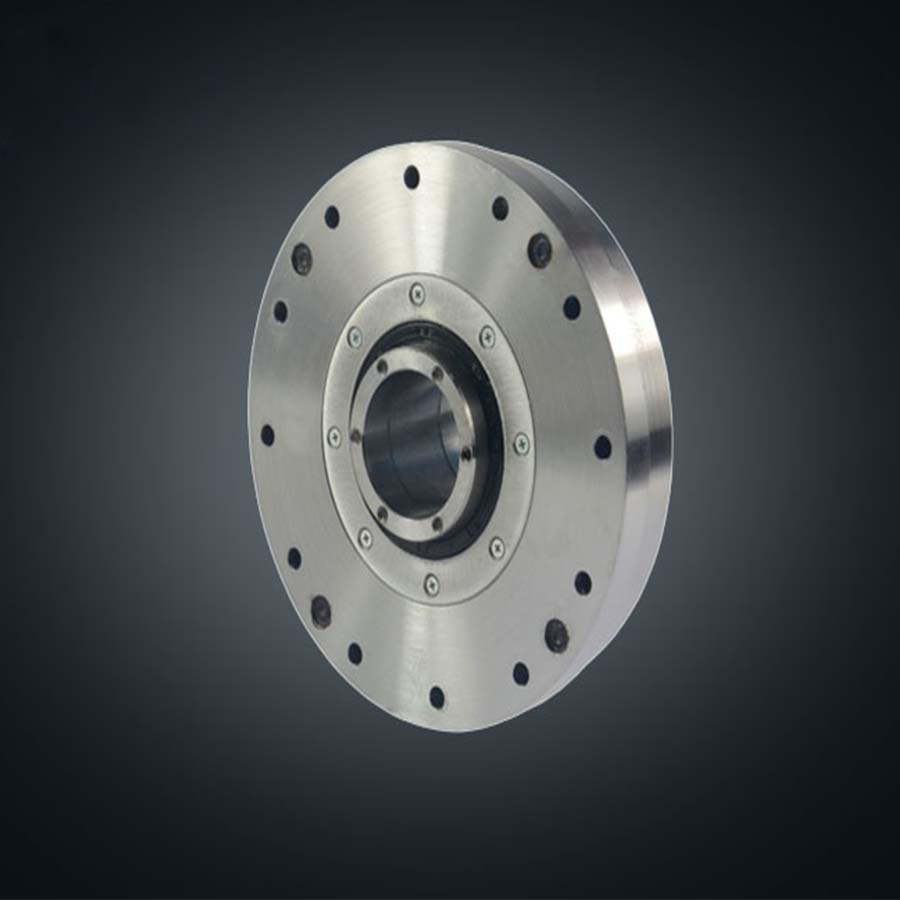

Harmonic Drive Gear CHD-III

Harmonic Drive Gear CHD-III (closed gear) for flange mounting.

Zero backlash, High dynamics, Lower production costs, Excellent lifetime precision, Consistent quality, Simple design solution, Compact, lightweight design.

Harmonic Drive Gear CHS-IV

Harmonic Drive Gear CHS-IV (closed gear) with shaft.

Zero backlash, High dynamics, Lower production costs, Excellent lifetime precision, Consistent quality, Simple design solution, Compact, lightweight design.

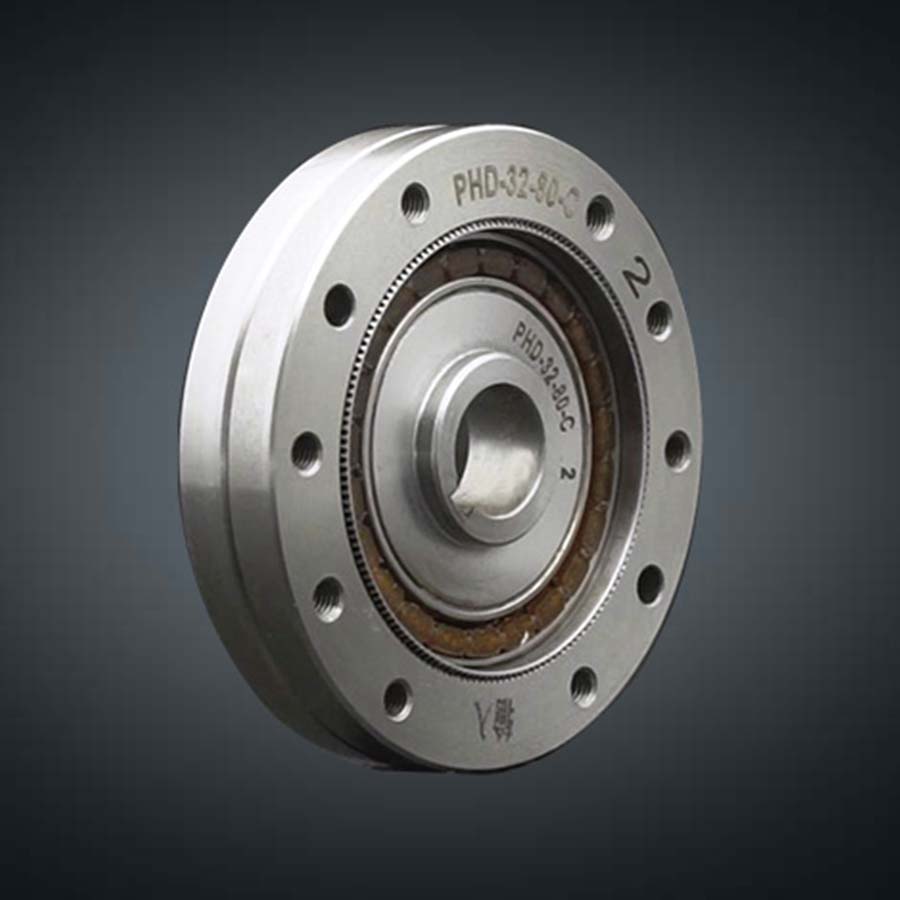

Harmonic Drive Gear PHD-C

Harmonic Drive Gear PHD-C (ultra thin gear).

Zero backlash, High dynamics, Lower production costs, Excellent lifetime precision, Consistent quality, Simple design solution, Compact, lightweight design.

Ordering and questions

Lars Peter Jørgensen

Product Manager, Motor & Gear

Phone: (+45) 44 83 08 06

E-mail: lajo@bondy.dk